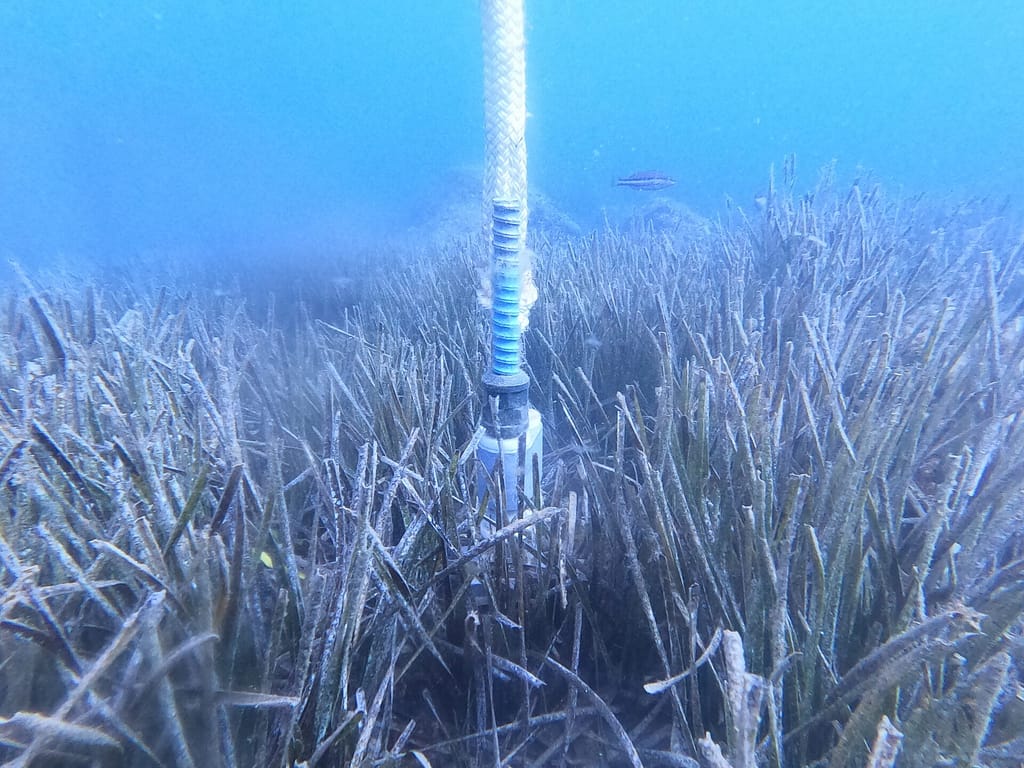

Underwater drilled anchors

Features of the Temano® drilled anchoring system:

- Pull-out resistance: 54 tons/anchor for the equivalent of 100kg of material

- Works on all types of seabed

- Reduces impact on the seabed 🌱

- Ground pressure lower than human step pressure

- Works with propylene glycol: colorless oil, water-soluble, and ocean-friendly

- Lifespan: 50 years and more with duplex stainless steel

3D rendering of mooring line with Temano® anchor :

Video of our underwater anchoring machine:

The steps to perform an underwater anchoring:

- Positioning

- Deployment of the drilling tripod

- Adjustment of the legs

- Drilling

- Injection of natural cement

- Anchor testing